From FABSHOP Magazine Direct

Interconnectivity was a dominating theme at Fabtech, and it is evolving into a new concept with a new buzzword, ‘Industry 4.0.’ Its meaning is broad and it will take some time to tame it into something useful, but it’s coming fast and it will affect us all.

By Larry Adams, Senior Editor

The Internet of Things (IOT). The Industrial Internet of Things (IIOT). Big data, the Cloud, Industry 4.0. These and other buzzwords have been flying around the last few years, but the buzz for the most part seemed to only briefly and intermittently touch the fabricating industry. You likely know that if you’ve been reading the pages of Fab Shop this year.

That flight plan altered perceptively as this interconnectivity concept landed at Fabtech; not with a thud or with a tentative toe, but with a resounding splash as equipment manufacturers of all sorts, from welding companies to waterjet manufacturers, laser suppliers to robotics developers, all made it clear that their machines could communicate with each other—as well as upstream and downstream vendors and end users—and that a shop floor could now be connected in this way whether via Industry 4.0, IIOT or some other nomenclature.

Just what is Industry 4.0, or its other related names, mean? That is the question that Editor Ed Huntress posed in his Editor’s Letter (see page xx), and while individual distinctions could probably be seen, the concept involves smart machines utilizing dedicated sensors and other information gathering devices, with some networking functionality that allows machines and planning systems within and outside of the workplace to better coordinate and optimize productivity.

According to Tobias Reuther, automation manager at Trumpf Inc., today’s interconnectivity technology allows manufacturers to “look at more than just a single machine, and look to the entire shop and the entire network of manufacturing.” One important goal, he added, is to use this data to add value to a job and remove as much of the non-value added activities as possible.

(These systems are also, in a sense, an homage to tomorrow’s workforce, that Matthew Fowles, global marketing manager for LVD Strippit, said is “far more IT knowledgeable than they are about cutting and welding. So, we are building that intelligence into the software.”)

ESAB WeldCloud

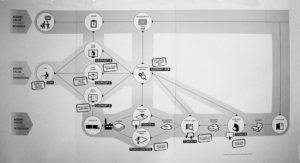

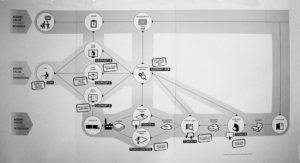

LVD Strippit showcased its interconnective capabilities both in the real world with a laser system and a panel bender operating using in situ data to create parts, and a virtual factory that they used for showing interested attendees how this concept can work in a fast paced, oft-changing factory floor in which customers are ordering smaller batches of parts that are often more complex than ever before.

“The company’s (LVD) philosophy over the years has always been what we call ‘integrated sheet metalworking’,” said Fowles. “Fifteen years ago, what that meant was being able to take an electronic part, take it through the CAM process and be able to make an accurate part, the first time. Now it is a lot more.”

But, LVD’s concept is a lot more than just 4.0, Fowles said showing a process map drawn on a wall of the booth depicting how a typical fab shop layout works.

At the show, they ran a live network of machines working with LVD’s centralized CADMAN database, said Fowles. “All of our machines are now social machines. All of our controllers are telling the central databases what they are doing at any given time.”

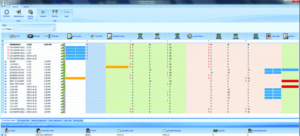

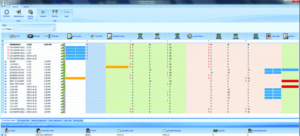

LVD CADMAN Job Part Manufacturing

The company’s CADMAN suite is LVD’s answer to full process integration between software and bending, laser cutting, and punching machines. It comprises a core database and works on different levels: interacting with ERP, efficiently classifying jobs with its CADMAN-JOB module and performs offline work preparation with its touch controls for bending and laser cutting, and interacts with the machines and the company’s Touch-i4 tablet to quickly view and analyze data.

Jamie Forsyth, LVD’s product specialist for offline software, said that CADMAN job can be set up on any PC for any user and gives an overview of what is going on in the entire workplace. In terms of a company ERP system, she said that orders that are sent into ERP are automatically flowed into the CADMAN software and everything that goes into that job is known. The system automatically determines such necessities as the required tooling and finds programming solutions to machining that part.

This could mean taking orders from multiple customers and nesting the parts to better optimize production or getting a rush job to replace bad parts.

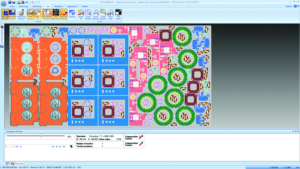

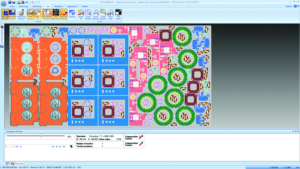

LVD Cadman-L Machining

While terminology is different, Trumpf also showcased multiple ways to better optimize production. Its TruTops Boost software integrates all design and programming capabilities, and eliminates the need to have different programs for different technologies.

In addition, Trumpf announced it had created a spin-off company called AXOOM that Reuther says supports the entire production value chain using Industry 4.0. Like LVD, the goal is to capture data—“anything, anywhere at anytime in real time,” Reuther said. This is true for better organizing jobs and how to run them, but it is also true for predictive maintenance and other quality related requirements.

“It used to be the industry would run a machine for a week and then we would go back and see how it went and then try to optimize the process. Now, with this method, it can tell you where to improve the process in real-time.”

LVD Strippit Cadman Chart

For instance, Reuther, pointing at a laser system, said that if that nozzle were starting to go bad, sensors on the machine would alert the operator, and perhaps even automatically order the required part. In all, he said that approximately 20 parameters on a laser cutter can be tracked and information on the machine or machine activity can be tracked.

The AXOOM system features an order management module, resource management module, and a logistics module. The foundation for the production planning module and the shop floor is a dynamic planning algorithm that responds instantly to rush orders or malfunctions and recommends solutions. After the production manager has signed off on the incoming order, suggestions for optimal production scheduling are automatically generated. The complex tasks of material provisioning and scheduling of machines and personnel – along with determining the sequence of processing steps – are optimized independently by the AXOOM platform, acting as a manufacturing advisor. On the shop floor, the operator can decline the advice.

LVD’s Jamie Forsyth operates tablet

Another company promoting its interconnectivity capabilities was Mazak Optronics, but in a slightly different way. In addition to its fabricating machines, Mazak has a substantial presence in the traditional chip making side of the metal working industry and as such has a lot of experience using MTConnect, an open protocol developed the AMT- The Association For Manufacturing Technology, that has been successfully tested by NIST and other groups to show how even very dissimilar machines and machine types can communicate with each other, said Dave Edstrom, chief technology officer for MEMEX Inc., the company that has partnered with Mazak to help analyze data collected by Mazak machines.

MEMEX’s “shop-floor-to-top-floor communications platform” is called Merlin and will work with Mazak’s new iSMART Factory concept that it says will harnesses the power of connectivity to optimize manufacturing operations at every level.

According to David Widlund, regional sales manager for Mazak, all the Mazak fabricating and metalworking machines come standard with MTConnect. “Now, we can take all the data out of the machine and go to the company that we have partnered with, Memex, and get a full dashboard on each machine, just like you would on the chip side.”

Another company utilizing Industry 4.0 is ESAB Welding & Cutting Products.In its huge, compound of a “booth” ESAB showcased a variety of welding technologies, and set among the mammoth space was an area dedicated to its new WeldCloud online data management platform. Weld Cloud integrates with other customer systems such as ERP, MRP, and QA to generate and analyze data.

Using any device with a web browser, users access applications and dashboards with functionality tailored for the job needs of different personnel: operations managers, quality managers, engineers, welders, maintenance staff, training supervisors, and others.

With WeldCloud, customers can facilitate traceability from single welds to the complete product utilizing a database that contains key information of every weld seam. It can develop weld schedules on a single machine, move them into the Cloud, and then push them out to other welding systems and remotely manage welding parameters, set limits, and set alarms for deviations.

It can also ensure complete documentation of filler metals, consumables, operator qualifications, and parameters, which is critical for companies that are required to keep this information for their customers or for standards certification agencies.

“While faster welding speeds and increased deposition rates reduce cycle time, automating activities that surround the welding processes enables users to make quantum leaps in productivity, quality and machine efficiency possible,” says Roul Kierkels, acting product manager for WeldCloud.

To see the full article please click here